Concrete vs Metal Ramp

When looking for the comparison between concrete ramp vs metal ramp we first need to look closely at the both ingredients. The carbon dioxide (CO₂) emissions associated with the construction of a ramp depend on several factors, including the materials used, the production process, transportation, and the overall lifecycle of the materials.

Concrete Ramps

Process:

- The production of cement, a key ingredient in concrete, is highly energy-intensive and generates a significant amount of CO₂. Cement production alone accounts for about 8% of global CO₂ emissions.

- The CO₂ emissions from concrete primarily come from the chemical process of calcination, where limestone (calcium carbonate) is heated to produce lime (calcium oxide), releasing CO₂.

Lifecycle Emissions:

- Concrete ramps are durable and often require less maintenance over their lifespan, potentially reducing emissions related to repair and replacement.

- Concrete can also sequester a small amount of CO₂ over its lifetime through a process called carbonation.

Concrete Ramp

Metal Ramps

Production Process:

- The production of metals such as steel or aluminum involves mining, refining, and manufacturing processes that are also energy-intensive and produce significant CO₂ emissions.

- Steel production, for instance, involves the reduction of iron ore in a blast furnace, a process that emits large amounts of CO₂.

- Aluminium production is even more energy-intensive due to the electrolysis process used in refining bauxite into aluminum.

Lifecycle Emissions:

- Metal ramps are typically more compact than concrete ramps, potentially reducing the amount of material needed and transportation emissions.

- Metals are recyclable, and using recycled steel or aluminum can significantly reduce CO₂ emissions compared to using virgin materials.

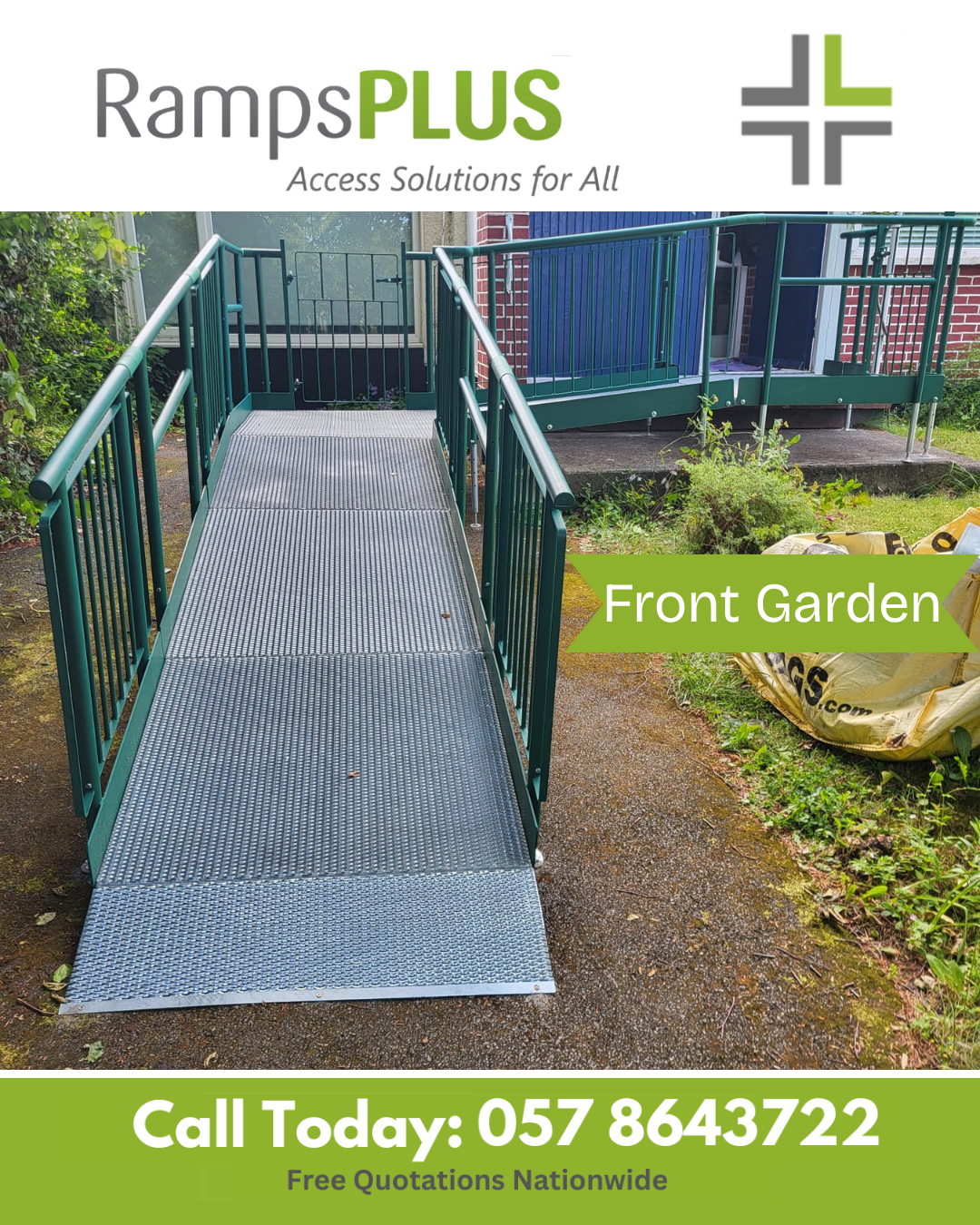

Metal Modular Ramp

Comparison and Conclusion

- Initial Production: Generally, concrete has higher initial CO₂ emissions per unit of material produced compared to steel when considering the same functional unit.

- Material Quantity: Concrete ramps may require more material due to the need for bulk and structural integrity, while metal ramps, being stronger per unit mass, might require less material overall.

- Recycling Potential: Metals have a high recycling rate, which can offset some of the emissions if recycled materials are used. Concrete recycling is less common and less effective in reducing CO₂ emissions.

- Concrete Ramp: Likely to produce between 3,000 and 5,000 kg of CO₂ for the same functional unit.

- Galvanised Steel Ramp: Likely to produce between 1,900 and 2,300 kg of CO₂ for the same functional unit.

-

- For a ramp requiring 10 cubic meters of concrete:

- CO₂ emissions = 10 m³ * 300-500 kg CO₂/m³ = 3,000 to 5,000 kg CO₂

- For a ramp requiring 1 ton of galvanized steel/metal (considering steel’s higher strength and lower volume requirement):

- CO₂ emissions = 1 ton * 1,900-2,300 kg CO₂/ton = 1,900 to 2,300 kg CO₂

- For a ramp requiring 10 cubic meters of concrete:

Result: A galvanised steel / metal ramp produces less CO₂ compared to a concrete ramp, considering similar functional requirements. This is primarily due to the higher emissions intensity of cement production and the larger volume of material needed for concrete structures.

Metal / Modular ramps are the future in housing adaptations. With less CO₂, recyclability, durability and cost effective, metal ramps are the quickly becoming the number one ramp solution in Ireland.

#metalramps, #modularramps